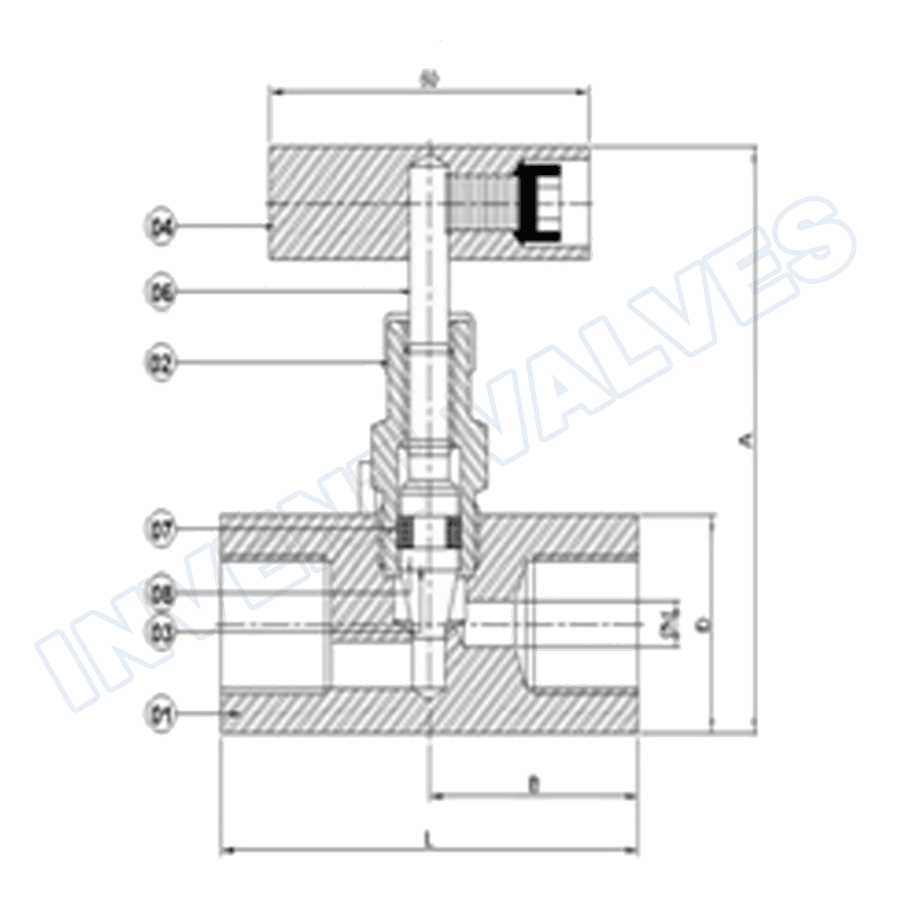

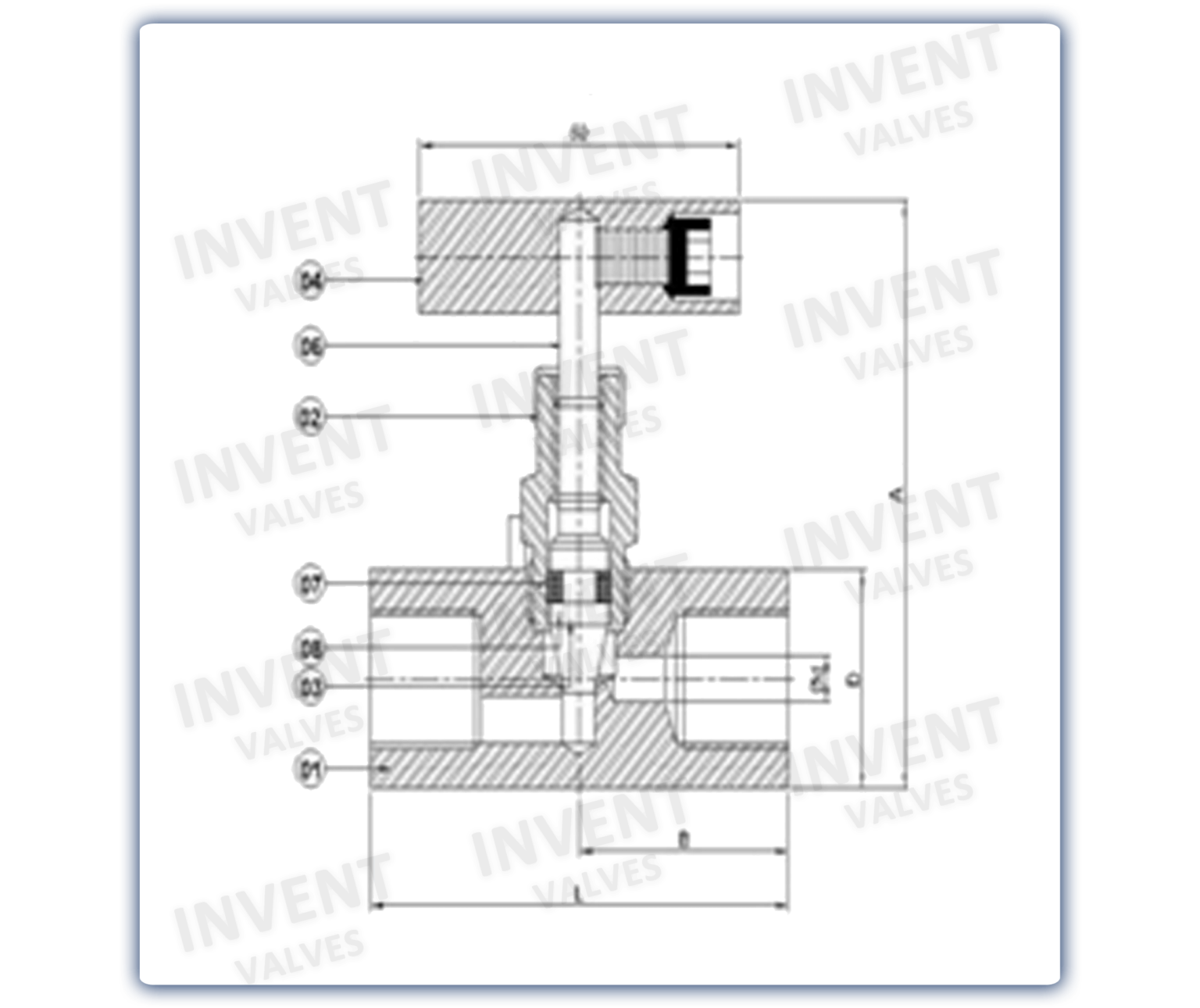

Needle Valve

The “INVENT” Ball Valves are economically priced and designed to last. These Valves provide exceptional performance in even the most stringent applications found in the Oil & Gas industry and other industries. We offer a wide range of elective seat and seal materials.

We are Manufacturing Needle Valves in Single Piece; Two-Piece & Three-Piece cast steel constructions. These Valves are manufactured to the highest possible quality standard. Many of our threaded and socket weld Ball Valves are manufactured according to the ASME B16.34 design standard. These valves provide the exceptional performance in even the most stringent applications found in the Oil & Gas industry and other industries. We manufacture high quality Trunnion mounted Ball Valve which are manufactured under, for more information contact us right now.

Features:

- Bar stock Needle Valve Design with back seated Blow out Proof.

- Stem- Ground and thread rolled

- Hard seat with non rotating stem tip with rotating stem tip regulating & Soft seat.

- Dust cap on bonnet pusher protects stem threads from external contamination. Packing and sealing are leak

- Tight for easy operation

- Low torque operating bar handle

- Extremely adjustable gland

- Bonnet lock pin fitted as standard for 6000PSIG and for high pressure lock plate as per the design required.

Specifications:

- Size –1/8” to 1”

- End connection :NPT,BSPT, Socket Weld , Butt Weld, Tube Fitting With Straight and angle pattern

- Working Pressure :3000, 6000 & 10000PSIG

- Temperature rating :PTFE 450?F, (232?C) / Grafoil 700?F (371?F)

- Material :S.S.316,S.S.304, C.S, F11

- Packing :PTFE, Grafoil, Panel Mounting on request

- All valves are 100% factory Tested at 10000 PSIG

- Lubrication :Day molly Sulphide

Optional Features

| Part Name | Material |

|---|---|

| Body | S.S.304 / S.S.316 / Carbon Steel |

| Bonnet | S.S.304 / S.S.316 / Carbon Steel |

| Gland | S.S.304 / S.S.316 |

| Handle | S.S.304 / S.S.316 / Carbon Steel |

| Handle Bolt | S.S.304 / S.S.316 |

| Spindle | S.S.304 / S.S.316 |

| Gland Seat | PTFE |

| Bonnet Locking Pin | S.S.304 / S.S.316 |

Materials Of Construction

| Part Name | Material |

|---|---|

| Body | S.S.304 / S.S.316 / Carbon Steel |

| Bonnet | S.S.304 / S.S.316 / Carbon Steel |

| Gland | S.S.304 / S.S.316 |

| Handle | S.S.304 / S.S.316 / Carbon Steel |

| Handle Bolt | S.S.304 / S.S.316 |

| Spindle | S.S.304 / S.S.316 |

| Gland Seat | PTFE |

| Bonnet Locking Pin | S.S.304 / S.S.316 |