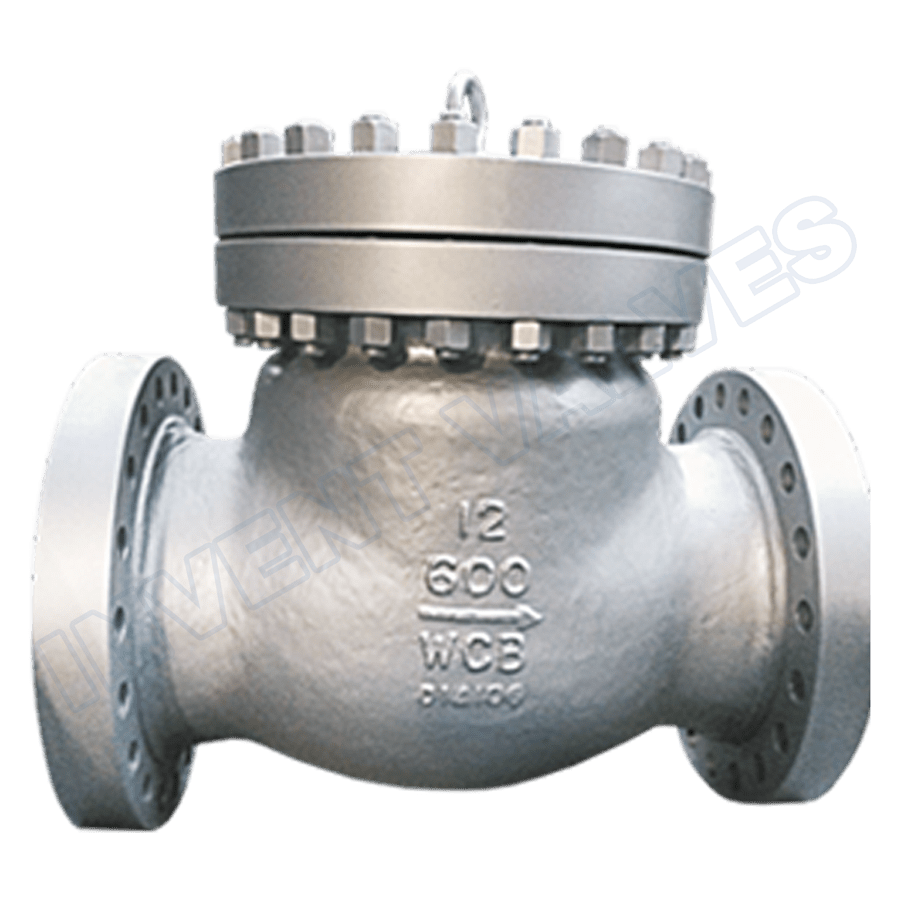

Check Valve

We are leading manufacturer, supplier and exporter of high quality Check valve. This valve allows a medium to flow in one direction. This valve ensures that the medium or fluid flows through a pipe in correct direction which can be known itself from its name as the fluid goes through one direction so its name is Check valve. These valves are easy to install and are designed in a way to handle maximum product pressure. Additionally these Check valve are made with high grade raw materials and manufactured in compliance with international standards.

Check valves are generally used with mixing loops in cooling or heating systems to make sure that the operation is accurate and to prevent back flow. There are various kinds of Check valves, for more information contact us right now.

Low Carbon Steel – LCB, LCC, etc.

Martensitic Steel – WC1, WC6, WC9, C5, C12, CA15, etc.

Austenitic Stainless Steel – CF8, CF8M, CF3, CF3M, CN7M, CG3M, etc.

Duplex Stainless Steel – CD4MCuN, CD3Mn, etc.

(Forged Valve) BS 5352 | API 602

(Forged Valve) 800# | 1500# | 2500#

(Forged Valve) 1/2" to 2"

Flanged | Socket Weld | Screwed | Butt weld (Forged Valve)

Materials Of Construction

| Sizes | DN15 to DN600 ( NPS 1/2 to NPS 24) |

|---|---|

| Pressure Rating | Class 150, 300, 600, 900, 1500 & 2500 |

| Material Construction | Cast Carbon Steel – WCB, WCC, etc. Low Carbon Steel – LCB, LCC, etc. Martensitic Steel – WC1, WC6, WC9, C5, C12, CA15, etc. Austenitic Stainless Steel – CF8, CF8M, CF3, CF3M, CN7M, CG3M, etc. Duplex Stainless Steel – CD4MCuN, CD3Mn, etc. |

| Design & Manufacturing Standard | BS 1868, API 594, API 6D, DIN 3230 |

| Face to Face Std. | ASME B16.10 |

| End Connection Std. | ASME B16.5 |

| Testing Standard | API 598 |

| Type of Bore | Standard (Full Bore) |

| End Connection Type | Flanged Ends, Screwed Ends, Socket Weld Ends, Butt Weld Ends, Victaulic Ends, etc. |

| Operated Type | Self Operated |

Materials Of Construction

| Part Name | Carbon Steel | Alloy Steel | Stainless Steel | |

|---|---|---|---|---|

| Body | A 216 WCB / WCC | A 352 LCB /LLC | A 217 WC6/WC9/C5/C12 | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Cover | A 216 WCB / WCC | A 352 LCB /LLC | A 217 WC6/WC9/C5/C12 | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Seat Ring | A 216 WCB/WCC+13% Cr./A 217 CA 15 | A 351 CF 8 | A 217 WC6/WC9/C5/C12+13% Cr. /A 217 CA 15 | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Disc | A 216 WCB / WCC+13% Cr. | A 351 CF 8 | A 217 WC6/WC9/C5/C12+13% Cr. | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Hinge | A 216 WCB / WCC | A 351 CF 8 | A 217 WC6/WC9/C5/C12 | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Hinge Pin | A 276 TP 410 | A 276 TP 304 | A 276 TP 410 | A 276 TP 304/316/304L/316L/321 |

| Side Plug | A 276 TP SS 304 | A 276 TP SS 304 | A 276 TP SS 304 | A 276 TP 304/316/304L/316L/321 |

| Joint stud | A 193 B7 | A 320 L7 | A 193 B16 | A193 B7³/B8 |

| Joint stud nuts | A 194 2H | A 194 7 | A 194 7 | A 194 2H³/8 |

| Gasket | Spiral Wounded SS 316 / 316L / 304 / 304L / 321 / A-20 with grafoil filler & PTFE filler | |||

| Disc nut | Stainless Steel | |||