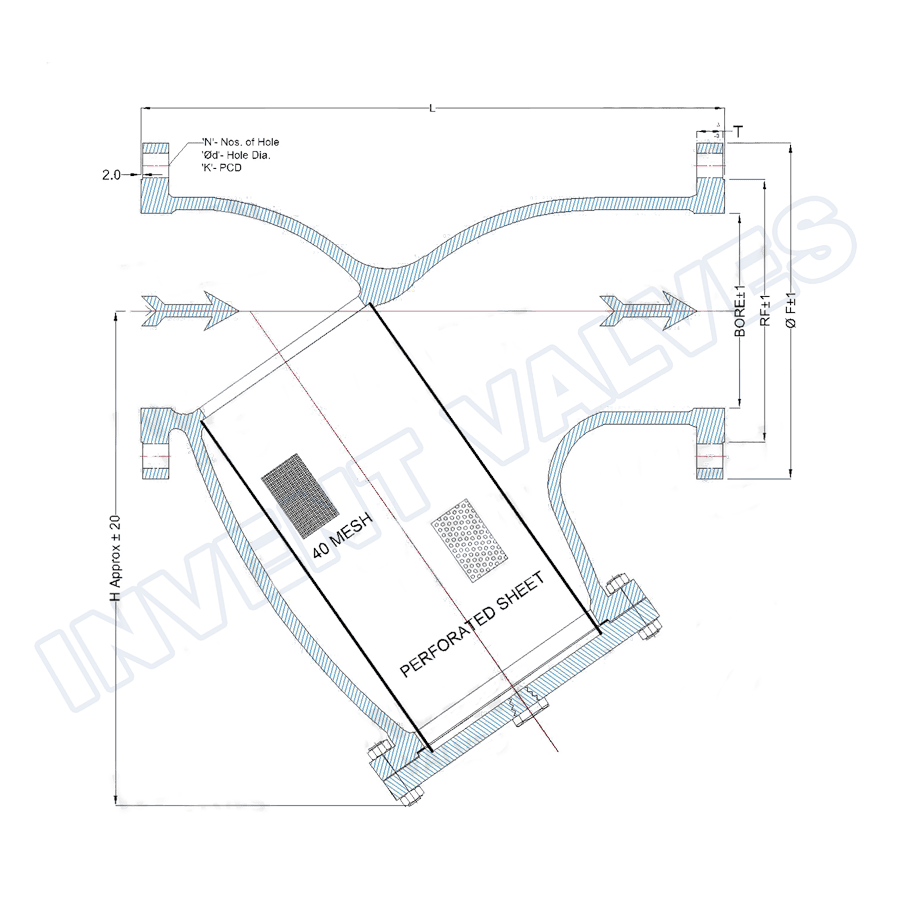

Casted Y Type Strainers Flanged/ Buttweld Ends

Y Strainer take their name from their configuration. are cast in sizes ¼” – 24″ with Threaded, Socket Weld or Flanged End connections. Strainer are your most economical choice for large debris removal. They are most commonly used in pressurized lines, gas or liquid, but can also be used in suction or vacuum conditions. Y-Strainer has the advantage of being able to be installed in either a horizontal or vertical position. However, in both cases, the screening element or “leg” must be on the “downside” of the strainer body so that entrapped solids can be properly collected and held for disposal.

Cast Y-Strainer and of course are available in most materials. Pressure ratings are ANSI 125# through ANSI 2500#. Standard body materials offered are Cast Iron, Ductile Iron, Cast Steel, Stainless Steel, Super Duplex. The Y-Strainer are equipped with a blow off port. A ball valve can be fitted to flush debris that is easily removable from the screen and exhaust to atmosphere or a drain system. This feature allows for easy cleaning without interrupting the process. Various Perforations, Mesh or Perforation Mesh combinations or Wedge Wire screens are available to meet your process requirements. We carry a large inventory so you don’t have to. Depend on Invent Valves for your shut down or construction delivery requirements. Check out our full line of strainers or for more information contact us right now.

Size: ½”- 24” (Flanged ends, Butt weld ends)

Rating: 150# to 2500#

Features:

- Wall Thickness as per AANSI B 16.34

- Compact Design

- Horizontal or Vertical Installations

- Large Screening Capacities

- Precision Machined Seats

Options:

- Larger Size and Pressure Rating

- P Tapings / Gauge

- Drain Valves

- Pleated Filter Element

- Magnetic Screen Insert

Low Carbon Steel – LCB, LCC, etc.

Martensitic Steel – WC1, WC6, WC9, C5, C12, CA15, etc.

Austenitic Stainless Steel – CF8, CF8M, CF3, CF3M, CN7M, CG3M, etc.

Duplex Stainless Steel – 4 A, 5 A, etc.

(Forged Strainer) 1/2" to 2"

(Forged Valve) Flanged | Socket Weld | Screwed | Butt weld

(Forged Valve) 800# | 1500# | 2500#

Materials Of Construction

| No. | Description | Carbon Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

|---|---|---|---|---|---|---|

| 1 | BODY | ASTM A 216 WCB | ASTM A 351 CF8 | ASTM A 351 CF3 | ASTM A 351 CF8M | ASTM A 351 CF3M |

| 2 | COVER | ASTM A 216 WCB | ASTM A 351 CF8 | ASTM A 351 CF3 | ASTM A 351 CF8M | ASTM A 351 CF3M |

| 3 | ELEMENT | SS 304 | SS 304 | SS 304L | SS 316 | SS 316 |

| 4 | STUD & NUT | ASTM A 193/194 Gr. B7/29 | ASTM A 193/194 Gr. B7/2H | ASTM A 193/194 ASTM Gr. B7/ 2H | ASTM A 193/194 ASTM Gr. B7/ 2H | ASTM A 193/194 Gr. 81/2H |

| 5 | GASKET | SS 316 SPW WITH GR FILLER | SS 316 SPW WITH GR FILLER | SS 316 SPW WITH GR FILLER | SS 316 SPW WITH GR FILLER | SS 3’6 |

| 6 | DRAIN PLUG | AS. A 105 | ASTM A 182 F304 | ASTM A 182 F304L | ASTM A -82 F316 | ASTM A 182 F316L |

| No. | Description | Carbon Steel | Stainless Steel | Stainless Steel | Stainless Steel | Stainless Steel |

|---|---|---|---|---|---|---|

| 1 | BODY | ASTM A 216 WCB | ASTM A 351 CF8 | ASTM A 351 CF3 | ASTM A 351 CF8M | ASTM A 351 CF3M |

| 2 | COVER | ASTM A 216 WCB | ASTM A 351 CF8 | ASTM A 351 CF3 | ASTM A 351 CF8M | ASTM A 351 CF3M |

| 3 | ELEMENT | SS 304 | SS 304 | SS 304L | SS 316 | SS 316 |

| 4 | STUD & NUT | ASTM A 193/194 Gr. B7/29 | ASTM A 193/194 Gr. B7/2H | ASTM A 193/194 ASTM Gr. B7/ 2H | ASTM A 193/194 ASTM Gr. B7/ 2H | ASTM A 193/194 Gr. 81/2H |

| 5 | GASKET | SS 316 SPW WITH GR FILLER | SS 316 SPW WITH GR FILLER | SS 316 SPW WITH GR FILLER | SS 316 SPW WITH GR FILLER | SS 3'6 |

| 6 | DRAIN PLUG | AS. A 105 | ASTM A 182 F304 | ASTM A 182 F304L | ASTM A -82 F316 | ASTM A 182 F316L |