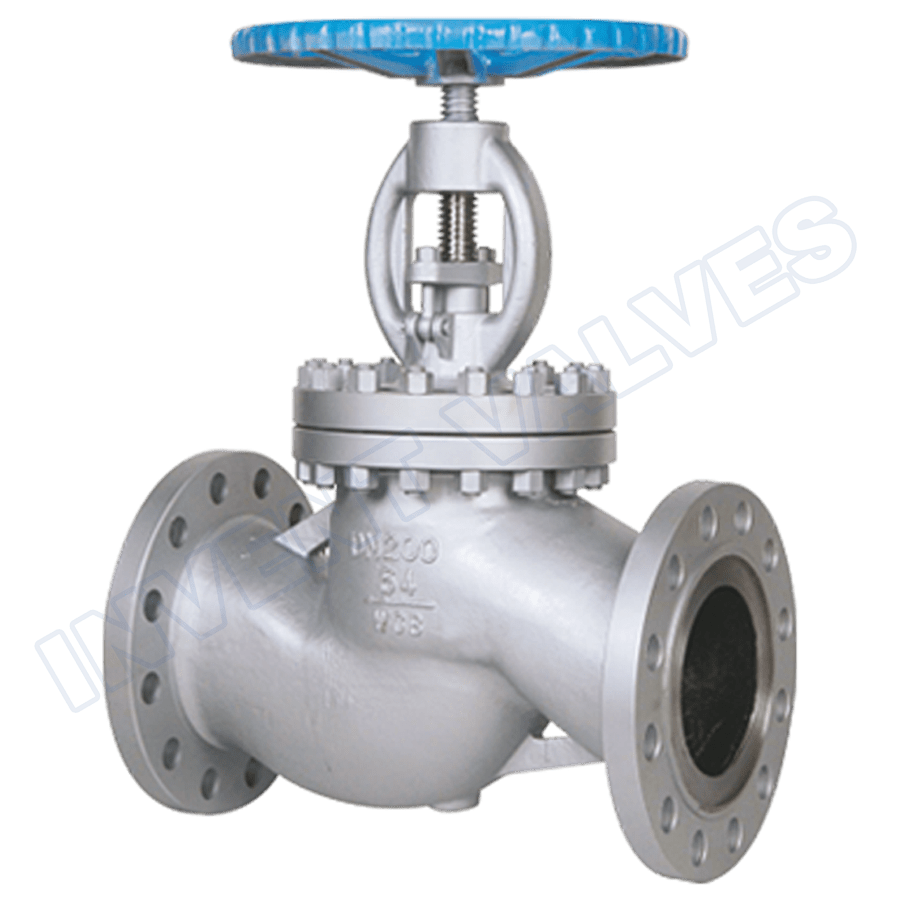

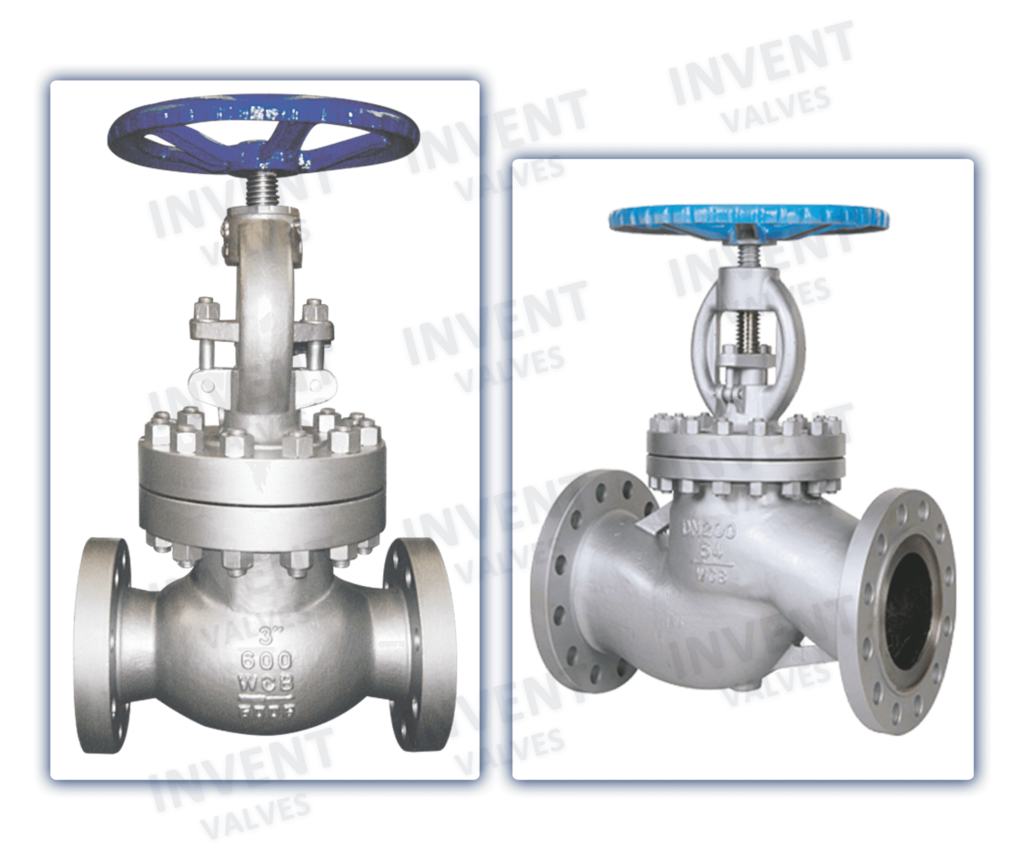

Globe Valve

Globe Valves are Outside Screw, Rising Stem, Bolted Bonnet Construction, threads are away from the line fluid and easy to lubricate. Globe Valve Manufacturer are generally available with Plug Type Disc, which is designed to give leak tight seating over a long period of in built wear life. industrial valve manufacturer, Globe valves body seat ring is shoulder type, threaded body seat ring which has large taper area that is for ample seating. Two nos. slots are provided on body seat ring, which is for easy removal for servicing at site. Designed for least possible obstruction to free flow by providing curvature turns in the body thereby minimising stresses & turbulence. The plug & seat-ring are machined and lapped very precisely to get a very tight sealing when valve is closed. Designed and manufactured to the highest standards of quality and, durability, for more information contact us right now.

Low Carbon Steel – LCB, LCC, etc.

Martensitic Steel – WC1, WC6, WC9, C5, C12, CA15, etc.

Austenitic Stainless Steel – CF8, CF8M, CF3, CF3M, CN7M, CG3M, etc.

Duplex Stainless Steel – CD4MCuN, CD3Mn, etc.

(Forged Valve) BS 5352 | API 602

(Forged Valve) 800# | 1500# | 2500#

(Forged Valve) 1/2" to 2"

(Forged Valve) Flanged | Socket Weld | Screwed | Butt Weld

Materials Of Construction Gate Valve

| Sizes | DN15 to DN600 ( NPS 1/2 to NPS 24) |

|---|---|

| Pressure Rating | Class 150, 300, 600, 900, 1500 & 2500 |

| Material Construction | Cast Carbon Steel – WCB, WCC, etc. Low Carbon Steel – LCB, LCC, etc. Martensitic Steel – WC1, WC6, WC9, C5, C12, CA15, etc. Austenitic Stainless Steel – CF8, CF8M, CF3, CF3M, CN7M, CG3M, etc. Duplex Stainless Steel – CD4MCuN, CD3Mn, etc. |

| Design & Manufacturing Standard | BS 1873 |

| Face to Face Std. | ASME B16.10 |

| End Connection Std. | ASME B16.5 |

| Testing Standard | API 598 |

| Type of Bore | Standard (Full Bore) |

| End Connection Type | Flanged Ends, Screwed Ends, Socket Weld Ends, Butt Weld Ends, Victaulic Ends, etc. |

| Operated Type | Hand Wheel, Gear Box, Electric Actuator, Bare Shaft, etc. |

Materials Of Construction Gate Valve

| Part Name | Carbon Steel | Alloy Steel | Stainless Steel | |

|---|---|---|---|---|

| Body | A 216 WCB / WCC | A 352 LCB /LCC | A 217 WC6/WC9/C5/C12 | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Bonnet | A 216 WCB / WCC | A 352 LCB /LCC | A 217 WC6/WC9/C5/C12 | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Seat Ring | A 216 WCB / WCC+13% Cr. | A 351 C F8 | A 217 WC6/WC9/C5/C12+13% Cr/A 217 CA 15 | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Plug | A 216 WCB+13% Cr. | A 351 C F8 | A 217 WC6/WC9/C5/C12+13% Cr. | A 351 CF8/CF8M/CF3/CF3M/CF8C |

| Spindle | A 276 TP 410 | A 276 TP 304 | A 276 TP 410 | A 276 TP 304/316/304L/316L/321 |

| Gland Flange | A 105 / CS | A 105 / CSA352/LCB/LCC | A 105/CS/217WC6/WC9/C5/C12 | A105³/CS³ /A351 CF8/CF8M/CF3 |

| Back Seat | A 276 TP 410 | A 276 TP 304 | A 276 TP 410 | A276 TP 304 / 316 / 304L /316 L /321 |

| Gland | A 276 TP 410 | A 276 TP 304 | A 276 TP 410 | A276 TP 304 / 316 / 304L /316 L /321 |

| Joint Sutd | A 193 B7 | A 320 L7 | A 193 B16 | A 193 B7³ / B8 |

| Joint Stud Nuts | A 194 2H | A 194 7 | A194 7 | A 194 2H³ /8 |

| Gland Stud | A 193 B7 | A 320 L7 | A 193 B16 | A 193 B7³ / B8 |

| Gland Stud nuts | A 194 2H | A 194 7 | A194 7 | A 194 2H³ /8 |

| Gasket | Spiral Wounded SS 316 / 316L / 304 / 304L / 321 / A-20 with grafoil filler & PTFE filler | |||

| Stem Packing | Braided Graphite and Die Formed Graphite ring / PTFE V-Ring | |||

| Yoke Sleeve | SG Iron / A439 Gr.D2 / Bronze | |||

| Hand whee | Below 2″= Malleable Iron & Above 2″ SG Iron / Fabricated Steel | |||